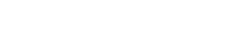

Technical Specification

| Maximum Input Power | 3,500 bhp | Stroke | 10” |

| Continuous Input Power | 3,500 bhp | Maximum Rod Load | 273,000 lbf |

| Maximum Speed | 190 rpm | Continuous Rod Load | 224,000lbf |

| Gearbox Ratio | 7.8:1 | Designed Life of Power End | >15,000 h |

| Number of Plungers | 5 | Pump Weight | 20,858 lbs |

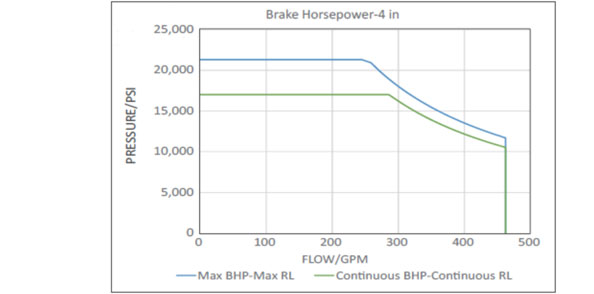

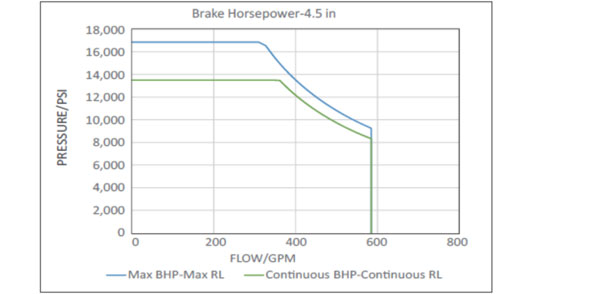

Performance Data

| Plunger Diameter | Displacement | Plunger Strokes and Flow per Minute | |||||||||

| in (mm) | Gal/Rev (L/Rev) | 80 | 100 | 120 | 140 | 160 | |||||

| GPM | PSI | GPM | PSI | GPM | PSI | GPM | PSI | GPM | PSI | ||

| LPM | Mpa | LPM | Mpa | LPM | Mpa | LPM | Mpa | LPM | Mpa | ||

| 4 | 2.72 | 217.5 | 21300 | 271.8 | 19881.8 | 326.2 | 16568.2 | 380.6 | 14201.3 | 434.9 | 12426.2 |

| 101.6 | 10.3 | 823.7 | 146.9 | 1029.6 | 137.1 | 1235.6 | 114.3 | 1441.5 | 97.9 | 1647.4 | 85.7 |

| 4 1/2 | 3.44 | 275.2 | 16850 | 344 | 15709.1 | 412.8 | 13090.9 | 481.6 | 11220.8 | 550.4 | 9818.2 |

| 114.3 | 13.03 | 1042.5 | 116.2 | 1303.1 | 108.3 | 1563.7 | 90.3 | 1824.4 | 77.4 | 2085 | 67.7 |

| Max Braking Power (BHP/KW) |

2999.7 | 2238.6 | 3500 | 2611.9 | 3500 | 2611.9 | 3500 | 2611.9 | 3500 | 2611.9 | |

| Input Speed (RPM) | 624 | 780 | 936 | 1092 | 1248 | ||||||

| Note: Above data is based on 90% ME & 100% VE, it may vary depends on operation condition. | |||||||||||